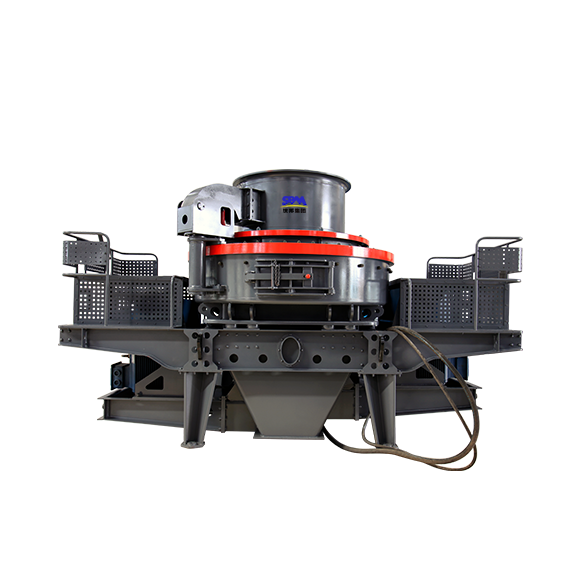

On the basis of introducing German technologies on sand-making machines and upgrading the VSI Sand Maker, SBM develops and researches a new generation of sand-making machine— VSI5X Sand Maker. VSI5X Sand Maker has multiple independent property rights and integrates 3 kinds of crushing modes. Now, VSI5X Sand Maker is the core equipment in machine-made sand industry.

VSI5X Sand Maker Working Principle

VSI5X Vertical-shaft Impact Crusher (also known as “Sand Maker”) has two feed modes – “feed at center” and “feed at center & sides”. As for the former mode “feed at center”, materials at the feed hopper firstly pass through the central hole into the high-speed spinning rotor. In the rotor, materials are fully accelerated and thrown outwards from the launching port to collide with a part of materials that freely fall after rebound. Next, materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening. As for the latter mode “feed at center & sides”, firstly, materials at the feed hopper pass through the circular hole. Then, materials are divided into two parts by the distributing tray. One part of materials enter the high-speed rotating impeller while the other part of materials fall from all sides of the tray. Materials in the impeller would be accelerated rapidly and thrown outwards at a high speed to collide with materials falling from all sides of the tray. Next, all materials hit the surrounding vortex material liner (or the impact block) inside the vortex chamber together. In the chamber, materials are bounced to the top of crushing chamber firstly and then change their direction by moving downwards to form a material curtain with materials emitted from the runner of impeller. Finally, finished products are discharged from the bottom discharge opening.