Energy-Efficient Stone Grinding Mills: Vertical Grinding Mill In the industrial grinding landscape, energy efficiency is a critical factor that can significantly impact operational costs and environ……

Engineer one-to-one for you, draw up plans in time, and provide investment estimates in time!

Online ChatGet PriceIn the industrial grinding landscape, energy efficiency is a critical factor that can significantly impact operational costs and environmental sustainability. The vertical grinding mill emerges as a leading solution for energy-efficient stone grinding. This article delves into the features, benefits, and applications of vertical grinding mills, optimized for search engine visibility.

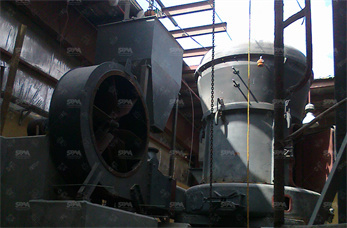

The vertical grinding mill is a modern grinding machine designed to enhance efficiency and productivity. Its vertical design allows for the effective use of gravitational forces to aid in the grinding process, making it an ideal choice for industries focused on energy efficiency and sustainability.

One of the standout features of the vertical grinding mill is its superior energy efficiency. Unlike traditional horizontal mills, vertical mills use less power to achieve the same level of grinding. This is due to their innovative design, which reduces energy consumption by utilizing the natural force of gravity to help with the grinding process. This leads to significant cost savings and a smaller carbon footprint.

Vertical grinding mills provide high performance and consistent results, which are essential for various industrial applications. They can produce finely ground materials with precise particle sizes, which is crucial for industries such as cement production, mineral processing, and chemical manufacturing. The uniform grinding process ensures that the final product meets stringent quality standards.

The energy efficiency of vertical grinding mills also contributes to environmental sustainability. These mills produce less noise and dust compared to traditional mills, creating a cleaner and safer working environment. Additionally, their lower energy consumption translates to reduced greenhouse gas emissions, helping industries comply with environmental regulations.

Vertical grinding mills are versatile and can handle a wide range of materials, including limestone, gypsum, coal, and slag. Their robust construction ensures durability and a long service life, even in demanding industrial conditions. This versatility and durability make them a valuable asset in various sectors, from construction to mining and beyond.

For businesses seeking energy-efficient stone grinding mills, the vertical grinding mill is an excellent choice. Its advanced design, superior energy efficiency, and high performance make it a standout solution for modern industrial needs. Investing in a vertical grinding mill not only reduces operational costs but also supports environmental sustainability, making it a smart choice for forward-thinking industries.

Powder Grinding Mill Performance Optimization Optimizing the performance of powder grinding mills is crucial for achieving maximum efficiency and productivity in industrial operations. Here are key ……

VSI Vertical-shaft Sand Maker is commonly known as the impact crusher or aggregate shaper. VSI Sand Maker is the fourth generation of high-performance sand-making machine developed by SBM on the bas……

As a classic primary crusher with stable performances, PE Jaw Crusher is widely used to crush metallic and non-metallic ores as well as building aggregates or to make artificial sand. PE Jaw Crusher……

Grinding Mill Safety And Operational Guidelines Ensuring the safety and optimal operation of grinding mills is essential for maintaining efficient production and protecting personnel. The European T……